Our dedication to being the icon of Steelmaking at KSRM is demonstrated in every phase of our extensively designed steel production process. From the initial Billet Charging Cradle, where the journey begins, to the final stages of bundling and stacking, our operations are orchestrated with unparalleled precision and expertise. The Billet Reheating Furnace and Pinch Roll serve as the gateway to a transformative process that defines our identity as "The ONE Steelmaker." Thermo Mechanical Treatment (TMT) in our dedicated chamber imparts a quenching effect, fortifying the rebar's strength to unparalleled levels, and forging our dedication to excellence. The Automatic Cooling Bed, a critical juncture in our process, ensures that the rebar is meticulously handled, reflecting our unwavering commitment to quality. This process culminates in the Cold Shear, a testament to our dedication to customization, meeting each customer's unique specifications. Through this intricate ballet of craftsmanship, we are delivering products of the highest caliber and integrity, setting new standards in the industry.

Inspection of Billet

Physical observation and Chemical Test by Spectrometer

Billet Re-Heating

Re-Heat the Billet to 1150°C - 1200°C in Furnace

Pinch the Billet slowly to Stand 1

Roughing Mill

Stand 1, 3, 5 for horizontal

Stand 2, 4, 6 for vertical

Shear #1

Cut the Crack Head of Running Stock

Intermediate Mill

Stand 7, 9, 11 for horizontal

Stand 8, 10, 12 for vertical

Shear #2

Cut the Dull Head and Tail of the Running Stock

Finishing Mill

Stand 13, 15, 17 for horizontal

Stand 14, 16, 18 for vertical

TMT (Thermo Mechanical Treatment)

Increase Strength of the Re-Bar by Quenching Effect

Cooling Bed

Partially Cool the Re-Bar by Natural Air

Quality Checking

Surface finishing, Surface Geometry, and Physical Strength and Bend Re-Bend Test of Re-Bar

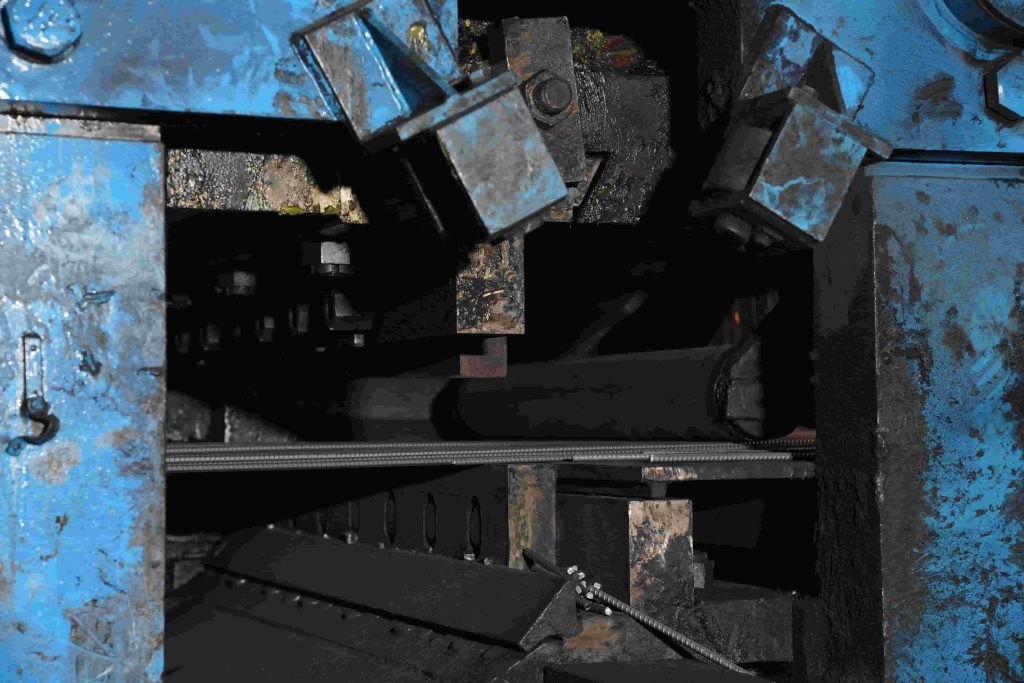

Cold Shear

Cut to 12 meters or Customised to Customer's Need

Bundling

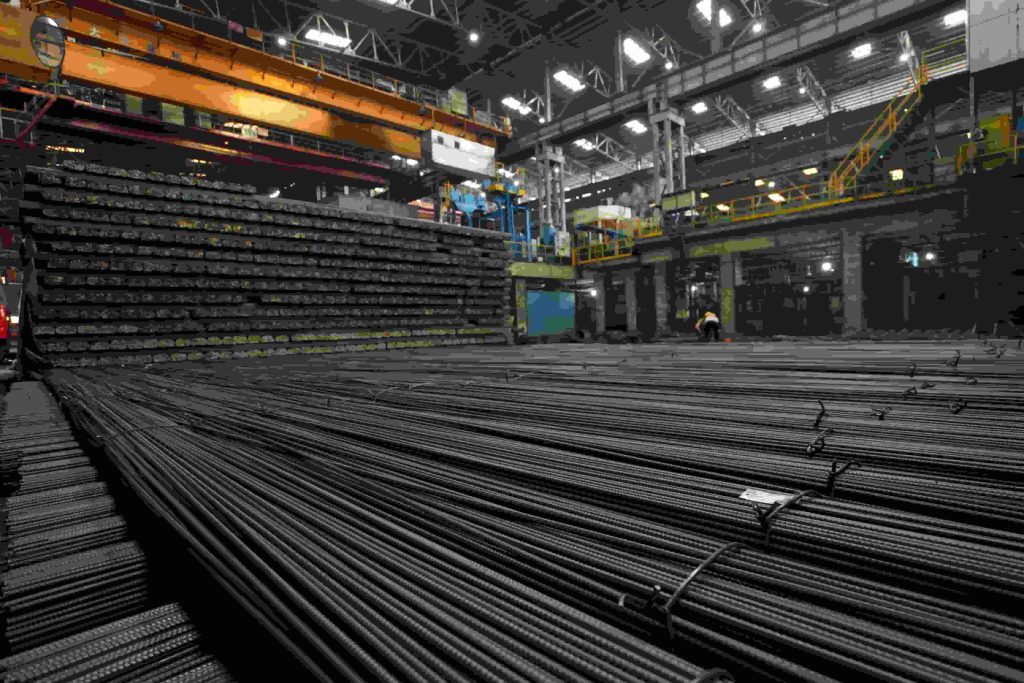

Bundled to 2.5 MT per bundle and Material Identification Tag

Stock

Stacking into Stock (According to Size and Grade)